3D Printing in Resin

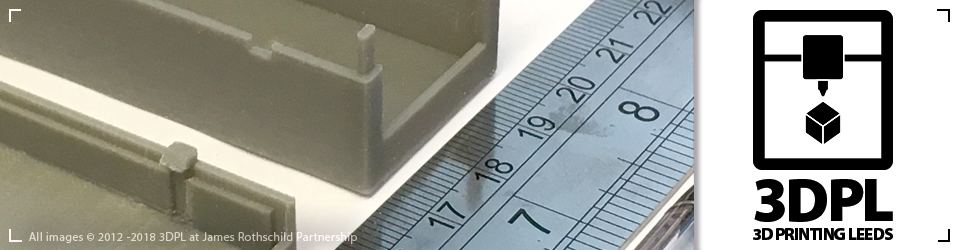

3D Printing Leeds has recently moved into MSLA Resin Printing and these new facilities were just what was needed for this replacement part for an old Dyson hoover.

Traditional FDM 3D printing struggles to get the … Read the rest...